Process Laboratories

Netherlands

Technology Qualification

Technology qualification is critical for process equipment with the following factors play an important role:

The need for unconventional process solutions has strongly increased.

New equipment needs to be thoroughly tested and characterized before it can be operated under field conditions.

Industries will not risk implementing untested process equipment. Mitigating the risks through proper technology qualification is critical.

ProLabNL’s test facilities are reliable and support fast and cost-effective technology qualification.

Technology Qualification

ProLabNL’s test facilities are reliable and support fast and cost-effective technology qualification.

The main objectives of qualification projects are typically:

- The verification of proper operational performance under realistic conditions

- The formulation of generally applicable design rules for a wide change of operating conditions

Three different important activities are necessary to reach these objectives:

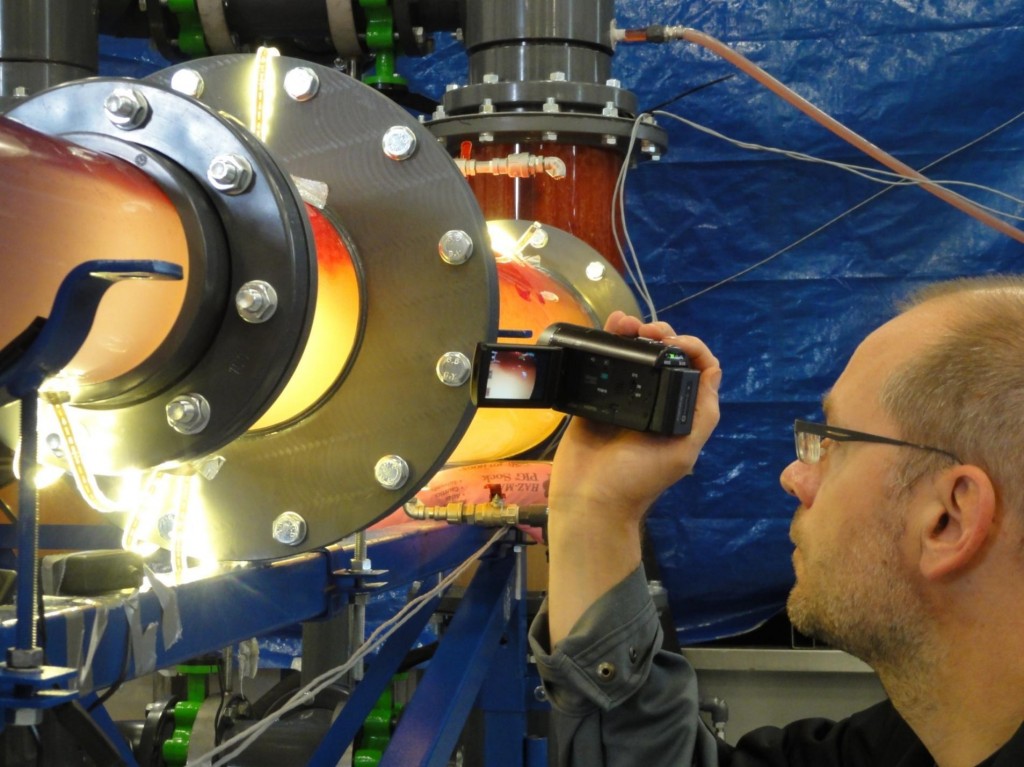

- Visualization of internal phenomena with various model oils under atmospheric conditions to enable thorough verification of CFD modelling results

- Large scale test under realistic conditions (full hydrocarbon, high pressure)

- Fluid properties characterization

The technology qualification process takes place in four (4) phases:

Phase 1:

- Analytical design work

- CFD modeling

- Optimization of design

Phase 2:

- Small scale testing with model fluids at atmospheric or low pressure

- Visual observation of tests (wherever possible / feasible) to correlate with CFD modeling results

Phase 3:

- Large scale testing with model fluids at atmospheric or low pressure

- Visual observation of tests (wherever possible / feasible) to correlate with CFD modeling results

Phase 4:

- Large scale testing with live fluids at high pressure simulating realistic field condition

The requirements for a successful qualification project are:

- Test conditions need to be as realistic as possible (both equipment scale and fluid properties)

- To identify and quantify physical phenomena that play a critical role, it is also necessary to carry out visual tests and simulations (e.g. CFD)

- Relevant experience / expertise for interpretation of test results is critical

These requirements are all covered by the expertise of our engineers and the characteristics of our flowloops, and enables ProLabNL to provide reliable and fast technology qualification in all the required phases of a project. In addition, ProLabNL can offer the following value-added benefits to your qualification projects:

- Tests with automated data acquisition and control systems

- Visual observation of tests (only in Low Pressure flowloops) to correlate with CFD modeling results

- Fluid characterization analytical laboratory on site

- Droplets size distribution analysis expertise with high speed cameras and laser diffraction measurements.

- Ability to customize flow loops (whenever feasible) to meet client’s test requirements

- Extensive experience with model fluids and live hydrocarbons (hydrocarbon gas and crude oils)

- Option for client to remotely observe the tests in real time

- Option for testing on-site using pilot units (Desanding HC skid, Deoiling HC skid, Test Separator, DUSEC Coalescer Skid)

ProLabNL has flow loops available to perform testing of the following third-party oil and gas process equipment and applications:

- Multiphase and Wet Gas flow meters

- 2 Phase gas-liquid separation (both conventional and compact process equipment)

- 3 Phase oil-water-gas separation (conventional and compact equipment)

- 4 Phase testing with mixtures of sand, oil, water and air (sand settling, erosion, fluidisation, slurry transport, etc.)

- Evaluation of flow regimes, slugging behavior in flowlines

- Droplet size measurement in oil/water flows, gas/liquid flows, etc.

- Produced water treatment equipment

- Other tests, subject to technical evaluation and feasibility of testing

An example of the technology qualification projects executed at ProLabNL is the “Accelerated qualification of a deep-water subsea separation system” as reflected in the poster below: