Process Laboratories

Netherlands

The ProLabNL testing equipment is designed to perform in the various stages of your technology qualification process. We design our equipment modular as to move between the various flow loops.

In recent years, it has become evident that clients require innovation and greater flexibility from their vendors or service providers to solve challenges in the field, which is why ProLabNL now offers skid-mounted separation equipment on short- or long-term rental basis, to be used by our clients to conduct field trials to select, understand, verify and improve technology. This approach helps our clients in evaluating and mitigating technical and financial risks prior to further major investment.

Depending on your process and requirements we can offer existing equipment or build you a custom solution. Please find a selection of our equipment below.

Bulk Deoiling Hydrocyclone Skid

The (Bulk) Deoiling Skid consist of the Bulk Cyclone Vessel [Tag: 01V20] and the Hydro cyclone Vessel [Tag: 01V21], interconnect piping and instrumentation.

The main process connections are 6″ and with the reject lines sized as 2″.

The vessels can be offered as individual units to test either cyclone type individually.

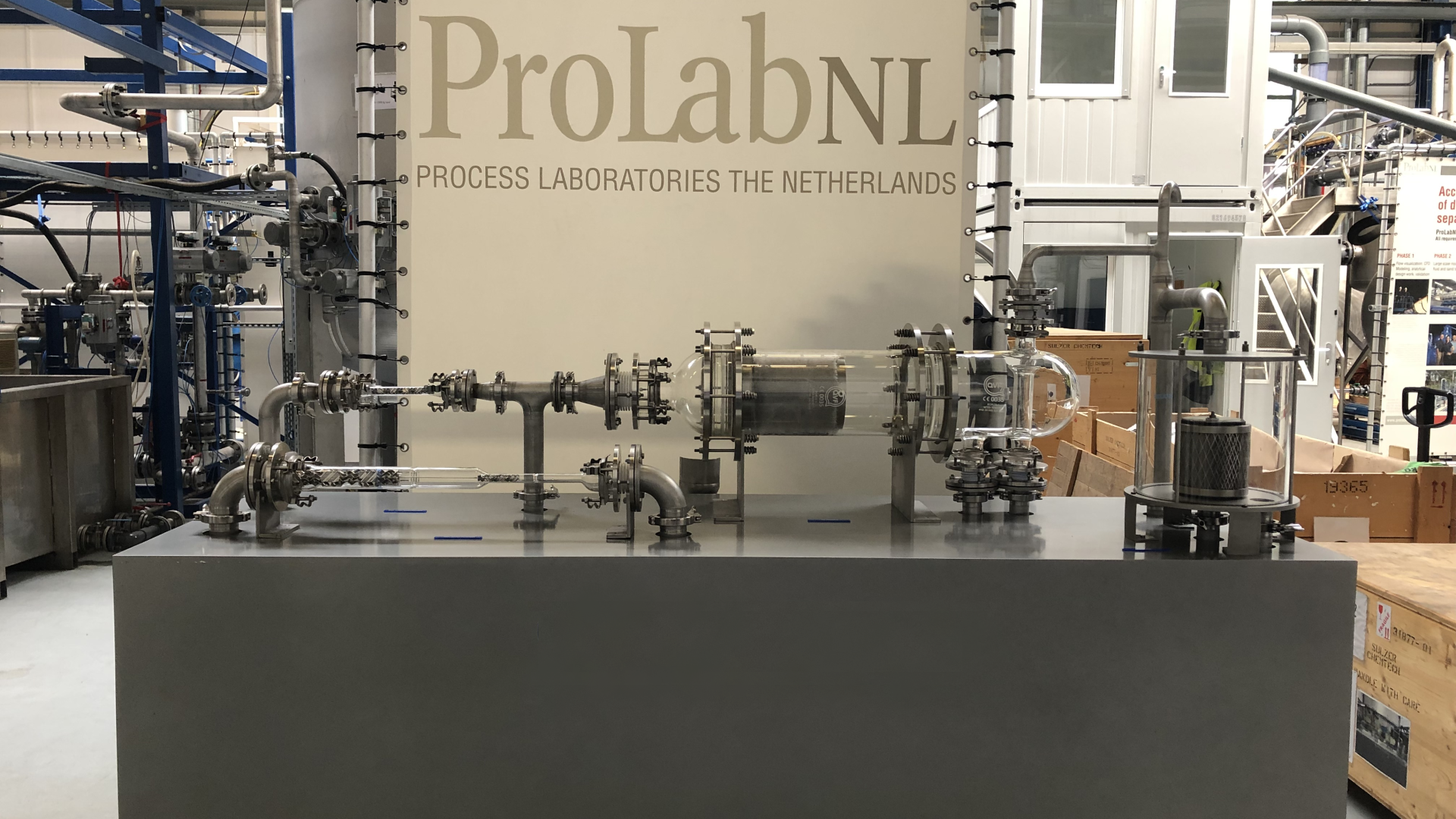

Bulk deoiling hydrocyclone skid in design

Bulk deoiling hydrocyclone skid as built

01 V 20; Deoiling Cyclone Vessel

42-off liner positions for 2.5″ liners (64mm / 34.9mm)

Design Pressure: FV / +90 barg

Design Temparature: -20 / 120 °C

Material of Construction: Duplex

Certification to: PED Cat.4 Fluid group 1 (Liquid & Gas)

01 V 21; Hydrocyclone vessel

61-off liner positions for 2.1″ liners (54mm / 25.4mm)

Design Pressure: FV / +90 barg

Design Temparature: -20 / 120 °C

Material of Construction: Duplex

Certification to: PED Cat.4 Fluid group 1 (Liquid & Gas)

The Bulk Deoiling Cyclone and Hydro Cyclone package is available to provide (temporary) capacity in your de-oiling needs as wel as technology validation of commercial cyclone liners in both testing environment and process facilities..

3-liner Bulk Deoiling Cyclone Skid

The 3-liner Bulk Deoiling cyclone test skid consists of a steel frame fitted with a vertical test vessel which can hold up to 3-off cyclone liners. Instrumentation can be added as per test requirements.

Specifications

3-off liner positions for 2.5″ liners (64mm / 34.9mm)

Design Pressure: FV / +10 barg

Design Temparature: 99 °C

Material of Construction: 316L (SS)

The bulk deoiling hydro-cyclone vessel can be fitted with polishing hydro-cyclones using adaptors and is ideal for testing and validating de-oiling cyclones in test loops or pilot plant environments.

C-4 Deoiling Hydrocyclone Skid

The C-4 Deoiling Hydrocyclone Skid consists of a steel frame fitted with a horizontal test vessel which can hold up to 4-off hydrocyclone liners. Instrumentation can be added as per test requirements.

Specifications

Number and size of liners: 4x 2″ or 4x 1″

Design Pressure: 48.4 / 0 barg

Design Temperature: 110 / -10 °C

Design flowrate: subject to liner’s specifications and number of liners.

Material of Construction: 316L (SS).

Dusec Coalescer Skid

The DUSEC test skid is liquid-liquid test vessel for demonstrating the DUSEC coalescer technology.

Specifications

1 position for 500mm long, 220mm OD, Dusec Cartridges

Design Pressure: +1 barg

Design Temparature: 200 °C

Material of Construction: Glass / SS.

Desander Skid

The skid-mounted Single liner desander is available for clients to conduct field trails to select, understand, verify and improve technology to separate unwanted sand or solids in their water (liquid) stream.

Single Liner Desander

1-off Desander liner (1″ and 2″)

Design Flowrate: 2 – 7 m3/h

Design Pressure: +10 barg

Design Temparature: 0 / 120 °C

Material of Construction: SS

Package dimensions (L x W x H): 1 x 1 x 2.5 (base offering).

Mixer Settler

Mixer Settler Demonstration Skid

Internals: Static Mixer, DC Meshpad, Dusec Cartridges

Material of Construction: Glass / SS.